HRC's commitment to carbon neutrality is not only carried out by facilitating the objectives of carbon footprint reduction from the target industries, but also by creatively building the closed recycling system for carbon fiber applications, meanwhile guiding every operation under the green mindset.

From raw materials to molding and recycling, each step is reinforced by patented technological barriers

-

Comprehensive Integration

Seamless integration of service stages supports carbon neutrality, enabling HRC and its clients to achieve more stable, efficient, and sustainable development together

-

In every step

By integrating circular economy principles at every stage of production, we maximize both economic and ecological value

This closed-loop system embodies the full realization of our vision, integrating sustainability, responsibility, and long-term value creation.

Comprehensive Composites Recycling Solutions

-

Waste Sorting

Material Sorting

Equipment and Process Planning

Solution Development

Fiber Quality Testing

-

Design & Implementation of Intermediates Solutions

Equipment and Process Planning

Material Property Formulation

Cost Assessment

Product Characteristics Testing

-

Generation of Recycled Products

Product Material Solution Design

Structural Analysis Evaluation

Production Process Planning

Finished Product Characteristic Testing

Regenerated products

Integrating patented recycling technology and validated carbon-neutral business models, HRC delivers high-quality regenerated products for transportation, construction, wind energy, and other industries, balancing both economic and environmental benefits.

-

r-CF Intermediate Products

-

End Application Products

-

-

Injection Molding Pellets

Injection Molding PelletsThe r-CF reinforced injection molding pellets exhibit excellent mechanical properties, making them ideal for manufacturing complex components widely used in the automotive, aerospace, and consumer electronics markets.

-

Non-Woven Fabric

Non-Woven FabricProduced from r-CF through dispersing, carding, and needle punching, this material effectively disperses fibers evenly while retaining their length. This product has excellent mechanical properties, it offers great potential for applications in SMC and RTM process materials, electromagnetic shielding, and anti-static products

-

Thermoplastic Felt

Thermoplastic FeltThis product features uniform fiber distribution, excellent mechanical properties, and high process flexibility, suitable for thermoplastic sheet aesthetics, laminate panel design, and manufacturing.

-

-

-

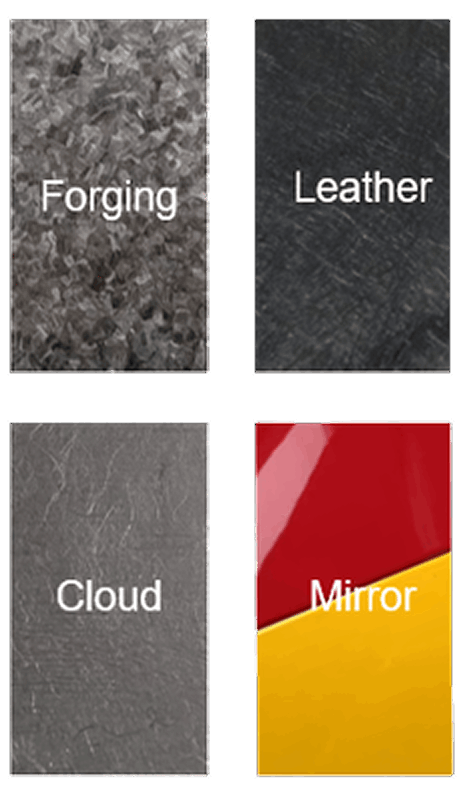

CFRTP Panel

CFRTP PanelCFRTP panels offer excellent strength and stiffness, superior corrosion resistance and durability. This product is ideal for flat panel manufacturing, providing diverse aesthetic effects, fast molding rates, and the benefit of reusability, making them suitable for applications in automotive surface decoration, architectural design, transportation vehicles, and sporting equipment.

-

Fully Recyclable Construction System

Fully Recyclable Construction SystemBy recycling, decomposing, and processing the waste from carbon fiber composite industrial products, this formwork system boasts exceptional qualities such as lightweight, high strength, and corrosion resistance, which significantly extend its usage lifespan.

-