The entire workflow—from specification definition and material selection to process and tooling design, as well as prototyping—is also covered by HRC, ensuring greater efficiency and high-quality results at every stage.

Molds, Tools, and Master Models: Maximum Precision & Versatility

HRC's tooling expertise ensures precision, scalability, and cost-effectiveness in every stage, enabling seamless production of complex composite parts

-

Tool engineering

Tool engineeringCustom tools for adhesive bonding, CNC milling, inspection, testing, and other processes.

- Delivers predictable, repeatable results

- Ensures compatibility with end-use applications -

Master models

Master modelsPrecision-machined and dimensionally stable reference units used to guide mould creation or as a quality-control standard.

- Guarantees consistency across multiple production runs

- Critical for maintaining exact geometries -

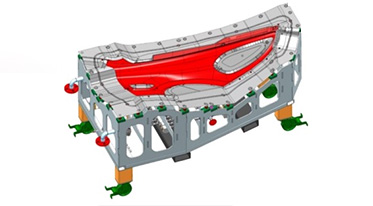

Mold production

Mold productionHigh-quality molds designed for long-term use, high-volume cycles, and consistent part replication.

- Ideal for high-temperature aerospace components or high-volume automotive applications

- Matched CTE tooling options available to ensure tight tolerances under varying thermal conditions -

Jigs & fixtures

Jigs & fixturesCustom solutions for adhesive bonding, CNC milling, inspection, and testing.

- Speeds up assembly and reduces errors

- Improves ergonomics and process efficiency

Prototyping Capabilities

-

3D CAD Design & Prototype Molds

Using advanced 3D CAD design tools, our team develops precise prototype molds, ensuring accurate material shaping.

-

Craft Prototyping

We fabricate prototype parts using specialized methods such as autoclave, RTM, or PCM, ensuring optimal strength and durability.

-

Real-World Testing & Iteration

Prototypes undergo rigorous testing under real-world conditions, refining design based on performance feedback.

-

Final Approval & Production-Ready Molds

After final approval, production molds are created, enabling efficient transition to mass production.