Our production facilities are equipped with globally leading, most comprehensive thermoset and thermoplastic manufacturing processes and equipment, capable of meeting diverse production demands.

Explore our key composite processes

-

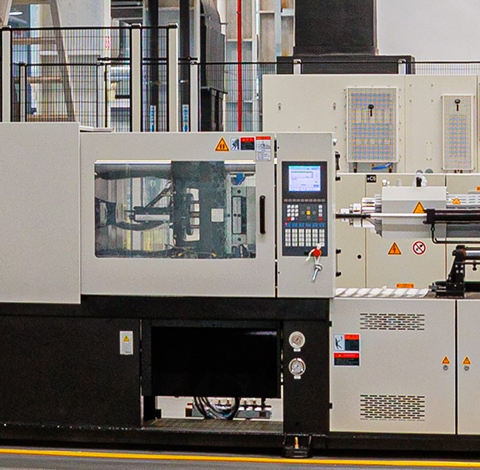

Injection MoldingInjection Molding

Injection MoldingInjection MoldingSuitable for mass production with short cycles and high efficiency

Capable of producing complex geometries products with high accuracy of dimensions

Consistent part quality with minimal post-processing

-

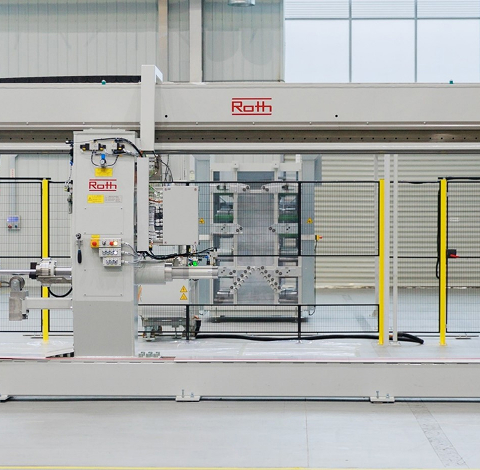

HP-RTMHP-RTM

HP-RTMHP-RTMProduces high-fiber-content parts with rapid cycle times

Suitable for structural automotive components and lightweight aerospace parts

Combines fast throughput with excellent mechanical properties

-

Wet compression moldingWet compression molding

Wet compression moldingWet compression moldingCost-effective method for semi-structural and interior parts

Reduces scrap and resin waste with precise control

Popular in automotive for underbody panels, battery trays, etc.

-

C-SMCC-SMC

C-SMCC-SMCCompression-molded carbon fiber offering high stiffness-to-weight ratio

Ideal for premium automotive parts, sports equipment, aerospace applications

Maintains strength while reducing overall part weight

-

PultrusionPultrusion

PultrusionPultrusionContinuous process for uniform profiles (rods, bars, beams)

High-speed and consistent fiber alignment

Widely used in infrastructure (bridge decks, ladders, pipes) and industrial sectors

-

PCMPCM

PCMPCMFast cycle times, high-volume potential

Suited for large or complex parts with controlled fiber orientation

Common in automotive exterior panels, large industrial components

-

AutoclaveAutoclave

AutoclaveAutoclaveHigh-temperature, high-pressure curing for premium part quality

Essential in aerospace and motorsports for advanced laminate consolidation

Delivers exceptional strength and finishing

-

Filament windingFilament winding

Filament windingFilament windingAutomated fiber placement on rotating mandrels

Perfect for cylindrical or spherical parts like pressure vessels or fuel tanks

Ensures optimal fiber orientation and uniform wall thickness

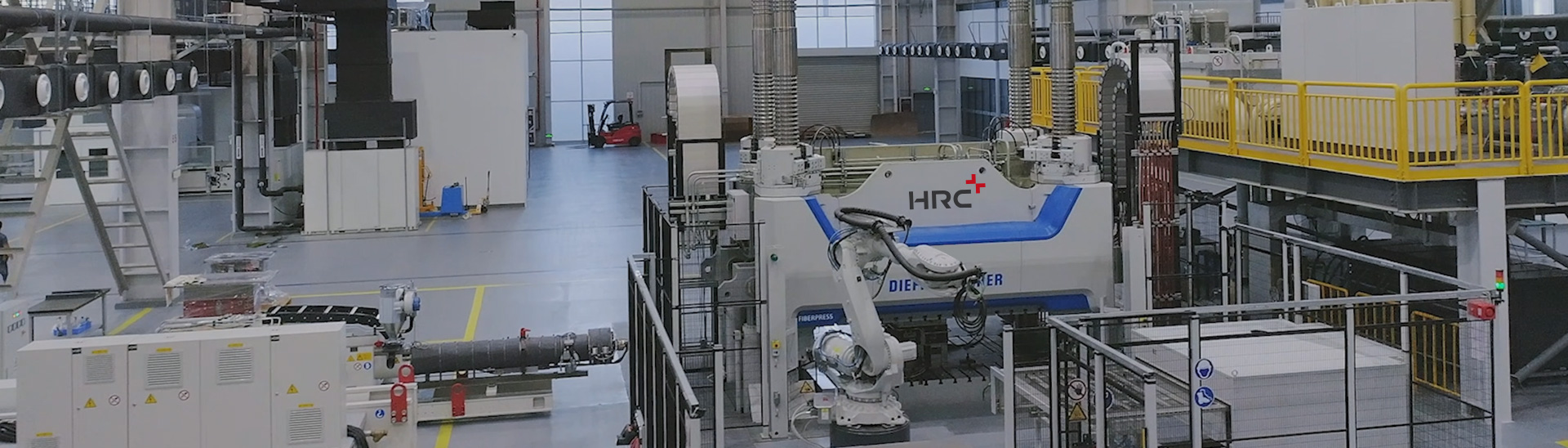

Our production facilities

-

HRC Auto

With 10 years of extensive experience in the automotive sector, HRC Auto is now a leading supplier worldwide of carbon fiber component development and manufacturing.

We work closely with OEMs from different continents, taking on challenging projects and delivering superior products that range from interior and exterior panels and structural components to monocoques, driving advancements in the automotive industry.

-

No. 58 Huangshan Road, Changshu, China

-

30,000 ㎡

HRC Auto

-

-

HRC Aero

HRC Aero specializes in the R&D, engineering, mass production, and assembly of aeronautic carbon fiber components and airframe structures.

We are now a trusted partner for large commercial aircraft and one of the main Tier 1 composite suppliers for the emerging low-altitude flight industries.-

Building E, No. 1150 Southeast Avenue, Changshu, China

-

20,000 ㎡

HRC Aero

-

Quality assurance

-

Using APQP for project management, methods include:

Failure Mode Effects Analysis (FMEA)

Statistical Process Control (SPC)

Measurement Systems Analysis (MSA)

8D, 5W, Six Sigma

-

System certification:

AS9100D

IATF16949:2016

Nadcap

DIN 6701

BS EN ISO 14001:2015